Drilling Machines: Introduction to Specialized Equipment in the Drilling Industry

Drilling rigs are among the most essential equipment in construction, mining, oil, and exploration projects. Depending on application, drilling depth, soil or rock type, and drilling system, these machines are manufactured in different models and brands.

Drilling Rig

A drilling rig is a mechanized system designed to penetrate underground layers. Based on their operating method, rigs are generally categorized as:

Rotary Drilling Rigs

Percussion Drilling Rigs

Core Drilling Machines

Horizontal Directional Drilling (HDD) Rigs

Water Well Drilling Rigs

The ultimate goal of a drilling rig is to extract minerals, collect core samples, or create boreholes for underground installations.

Core Drilling Machine

One of the most common machines in exploration drilling, the core drilling machine is used to extract cylindrical core samples from underground layers. These cores provide valuable geological and structural information.

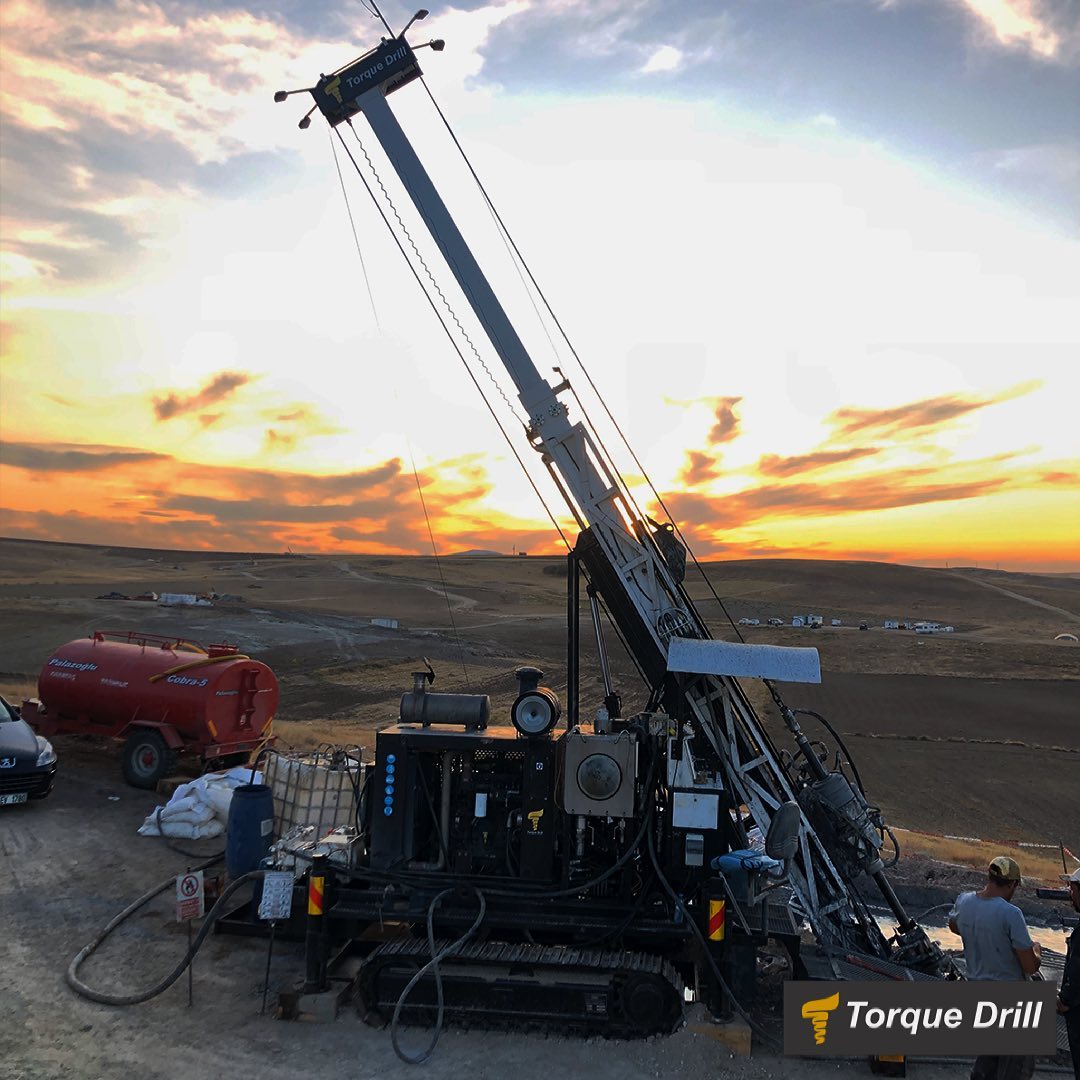

Torque Drill

Torque Drill systems are specialized rigs focusing on torque control and transmission during drilling. Designed for hard formations, these machines deliver high efficiency and accuracy thanks to their advanced power transmission systems.

Spindle

The spindle is the central power transmission unit in a drilling rig, responsible for rotating the drill rods and bit. Smooth and vibration-free spindle performance is crucial for effective drilling, particularly in vertical core drilling machines.

Winch

The winch system is used to raise and lower drilling equipment and accessories. Equipped with heavy-duty wire ropes or cables, winches typically operate through electric or hydraulic control systems.

Crawler Drilling Rigs

Some drilling machines are track-mounted (crawler rigs) to ensure mobility in rough terrains, mountainous areas, and mining sites. This feature greatly improves flexibility and maneuverability in challenging environments.

Wireline Drilling System

Modern rigs often employ the wireline system, which allows faster and safer core retrieval compared to traditional methods. It is particularly effective in deep drilling projects.

Applications of Drilling Rigs in Different Industries

Mining: Exploration of metallic and non-metallic reserves

Geotechnical: Soil strength analysis and geological surveys

Water Wells: Drilling wells for residential, agricultural, and industrial use

Oil & Gas: Exploratory and production well drilling

Choosing the Right Drilling Rig

When selecting a drilling machine, the following factors should be considered:

Target drilling depth

Type of soil or rock formation

Portability (crawler-mounted vs. stationary)

Engine and spindle power

Availability of winch and automation systems

Drilling rigs are the beating heart of subsurface operations, playing a critical role in the success of mining, geotechnical, and exploration projects.

Purchase Drilling Machines from Sang Tarash Company

With years of experience in supplying drilling equipment and machinery, Sang Tarash Company offers modern core drilling rigs, wireline systems, mud pumps, and related components. If you are looking for quality, after-sales service, and professional support, we are ready to provide expert solutions tailored to your drilling projects.